Quality Control Points In Cylinder Production

After-sales service guarantee of Shandong Hongsheng Pressure Vessel Co., LTD

(Shandong Zhisheng International Trade Co., LTD.)

1、 High standard of products from a good source - from the source, the control of raw materials into the factory inspection

Our company produces all products, in every production process will strictly control the quality of products, from the source, we select raw materials must have production qualification, must issue the original product quality certificate, to ensure that the raw materials selected meet the requirements of gas cylinder production.

One, raw material warehousing inspection

1) The supplier shall provide materials: original product quality certificate;

2) According to the standard requirements of Shandong Hongsheng Raw material Inspection factory, check: appearance, outer diameter, wall thickness and chemical composition of seamless steel pipe.

1. The appearance inspection of seamless steel pipe shall ensure that the product is free from any deformation, scratch, pitting and other defects affecting the product performance;

2. The outer diameter of seamless steel pipe shall be ±1% of the nominal outer diameter (hot rolled) and ±0.75% of the nominal outer diameter (cold rolled) specified in GB/T18248-2021;

3. The wall thickness of seamless steel pipe is hot rolled (-10%~+12.5%) and cold rolled ±10% according to the nominal wall thickness stipulated by GB/T18248;

4. The analysis of metal chemical composition in seamless steel pipe shall be conducted according to the detailed provisions of GB/T18248-2021 and TSG23-2021 on chemical composition.

The list of ingredients is as follows: List of chemical composition (mass fraction) /%

| Mark | C | Si | Mn | P | S | S+P | Cr | Mo | V | Ni | Cu |

| 37MN | 0.34 ~ 0.40 | 0.10 ~ 0.30 | 1.35 ~ 1.75 | ≤ 0.015 | ≤ 0.010 | ≤ 0.020 | ≤ 0.30 | - | - | ≤0.30 | ≤0.20 |

| 34CrMo4 | 0.30~0.37 | ≤0.40 | 0.60 ~ 0.90 | ≤ 0.015 | ≤ 0.010 | ≤ 0.020 | 1.9 ~ 1.2 | 0.15 ~ 0.3 | - | ≤0.30 | ≤0.20 |

5、Cylinder quality traceability from the source, each cylinder at the bottom of the imprint transplant number, to ensure the traceability of cylinder products.

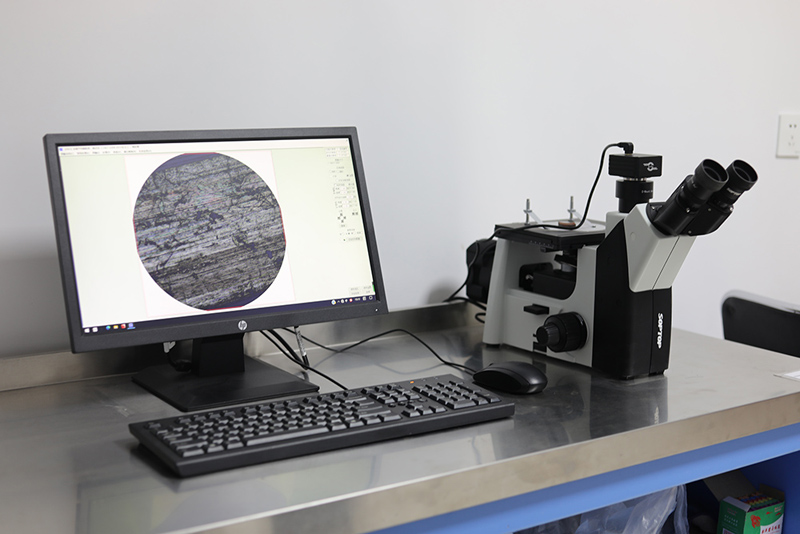

Two, seamless cylinder test center

We have a sound seamless cylinder testing center, each batch of products, after strict testing, can enter the next process of production, to ensure that the products really meet the requirements of production standards, to ensure the delivery of qualified products to customers.

Through the above inspection, we can choose high-quality materials for customers, and strictly control the production process, to ensure that we can deliver qualified products of excellent quality for customers, to avoid the late products due to quality problems such as safety risks.

2、 Product quality control

In order to ensure the smooth implementation of the customer's distribution plan, according to the requirements of production, supply and sales, the sales department, quality inspection Department and production and supply Department cooperate with each other to clarify their responsibilities and ensure the successful completion of the project according to the requirements of the product negotiation.

Our production and quality inspection personnel have decades of experience in the gas cylinder industry, and are fully capable of ensuring the smooth implementation of products. Production workers are through strict technical training, can ensure the normal production of qualified products.

1) Products are produced in full accordance with order standards such as ISO9809-3, ISO9809-1, GB/T5099.3.

2) All products have gone through strict inspection procedures, according to the batch of blasting test, as well as water pressure and air tightness test, to ensure that the products meet the quality requirements before leaving the factory.

3) For each production order, we will hold a production technical meeting before production, and display the order information on the workshop screen at any time to ensure zero error.

3、 Communication zero distance - 24 hours technical consulting service support

After our company to ensure that products are sold, when the guest products use problems, help guests to solve the problem as soon as possible, using 7 x24 hours of telephone, online and other way of technical advisory services, each of our sales staff, is thought a sales engineer, for the product performance, technical essentials are very proficient.

In the process of using the product, users can provide timely and effective technical services, timely determine the solution, as soon as possible to restore the product function.

4、 Because of trust, can be worth having

Every employee of Shandong Hongsheng, strict control of the process of each link of the product, to ensure that we have good confidence to provide you with perfect service.

We will also provide the relevant cylinder operation precautions and safety precautions from time to time, to ensure that users can really rest assured when using.

Shandong Hongsheng Pressure Vessel Co., Ltd. is willing to be your long-term partner and chief cylinder safety officer, and jointly escort your cylinder safety.